- Sectors

- Aerospace & Defense

- Big science

- Fintech

- Insights

ARQUIMEA offers design and manufacturing engineering to avoid intermediaries and work with a single interlocutor, reducing risks and saving costs.

Our advanced design software tools and the teams’s expertise in all stages of manufacturing engineering allow us to reduce risks and costs for our customers. In addition to design documentation, we also offer ILS services suchas user and maintenance manuals, technical publications and IPL illustrations. We also maintain agreements with research centers and certified laboratories to further develop our research, such as CIEMAT.

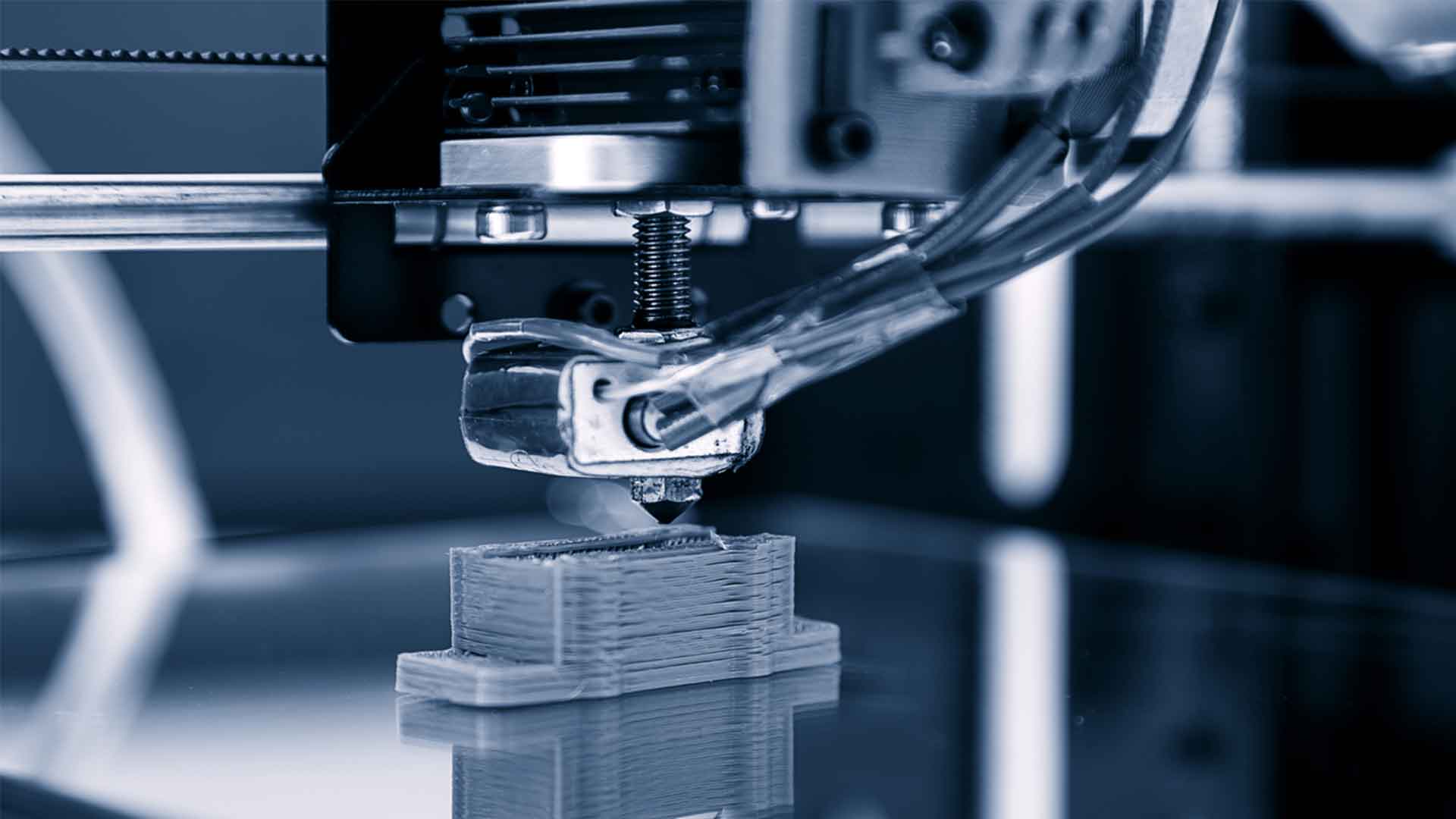

We have also mastered metal Additive Manufacturing (AM), which allows the production of highly complex parts through the addition and sintering of material. We use this technology for the manufacture of our most complex parts, although it is also suitable for short series and first prototypes, as well as for the industrial production of parts with sophisticated requirements.

Our resources include computer aided design, engineering and manufacturing tools, machining, welding and testing machinery, metrology lab and clean room with thermal vacuum chamber.

ARQUIMEA’s high-end resources allow us to meet our customers’ requirements with guarantee and repeatability. Our processes are approved for special works such as electroerosion, welding, laser marking, visual inspection and penetrating liquids.

Some examples of projects he has worked on include parts on Mars, on the International Space Station, equipment on large telescopes, on Rolls-Royce aeronautical turbines, at CERN, work for Eurofighter, A400M, etc.

Contact us, set us a challenge and discover everything we can offer you.